A Pre-Delivery Inspection (PDI) is a vital quality control process for high-performance vehicle repairs, ensuring vehicles meet top standards before delivery. It includes evaluating engine performance, electrical systems, interior/exterior conditions, and verifying repairs like dent or body restoration. PDI provides peace of mind for owners and showcases mechanics' expertise, enhancing customer satisfaction and preserving vehicle performance. However, challenges like inadequate training or focusing only on visible components can undermine these benefits, requiring specialized services for underlying issues.

In the high-performance automotive sector, a meticulous pre-delivery inspection (PDI) is paramount. This critical step ensures that vehicles meet stringent quality standards before reaching buyers. Our article guides you through essential PDI procedures and key components to assess during repair evaluations. We explore the benefits of rigorous quality control and highlight common pitfalls to avoid. By understanding these aspects, mechanics can deliver top-notch repairs, fostering customer satisfaction and maintaining the reputation of high-performance vehicle brands.

- Understanding Pre-Delivery Inspection Procedures

- Key Components to Assess During Repair Evaluation

- Ensuring Quality: Benefits and Common Pitfalls

Understanding Pre-Delivery Inspection Procedures

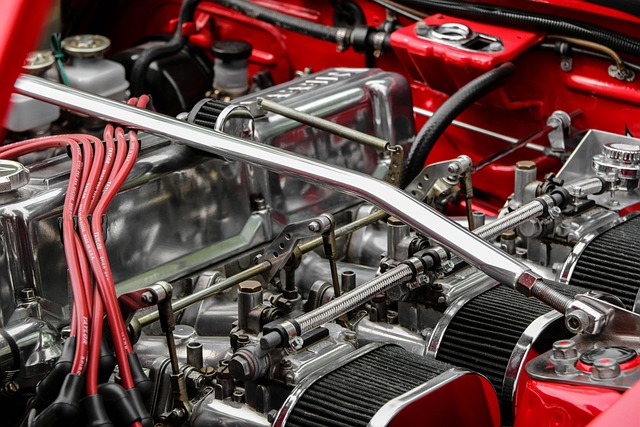

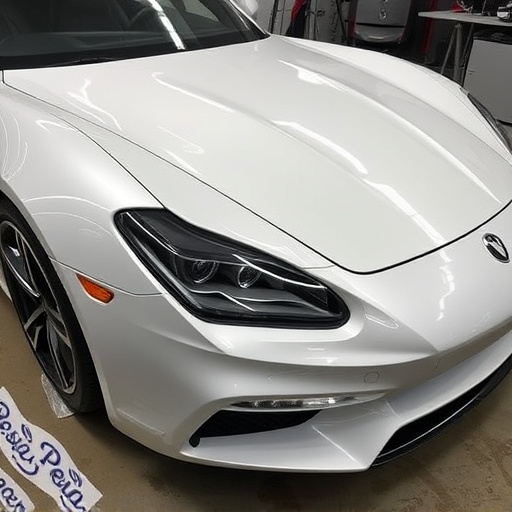

A pre-delivery inspection is a meticulous process designed to ensure that high-performance vehicles meet the highest standards before they hit the road. This critical step involves a comprehensive evaluation covering everything from engine performance and electrical systems to exterior and interior conditions. It’s not just about identifying defects; it’s also about verifying that all repairs, including specialized services like vehicle dent repair or car body restoration, have been executed flawlessly.

This procedure is crucial for both the owner and the mechanic. For owners, it offers peace of mind, ensuring their high-performance machine is safe and ready to dominate the streets. For mechanics, it serves as a quality control measure, allowing them to showcase their expertise in car repair services and ensure customer satisfaction.

Key Components to Assess During Repair Evaluation

When conducting a pre-delivery inspection for high-performance vehicle repairs, several key components must be meticulously assessed to ensure top-tier quality and performance. The process should start with a comprehensive visual inspection, looking for any signs of damage or misalignment that might have occurred during the repair process. This includes checking the body panels, fenders, doors, and hood for cracks, dents, or uneven paint jobs—all indicators of subpar frame straightening or auto body shop practices.

Additionally, the inspection should delve into crucial mechanical aspects such as engine functionality, transmission performance, brake system integrity, and suspension alignment. In high-performance vehicles like Mercedes Benz models undergoing collision repair, every detail matters. Even slight discrepancies in these areas can affect handling, speed, and overall driving experience. Therefore, a thorough evaluation by a trained technician is paramount to guarantee the vehicle meets its original performance standards before delivery to the customer.

Ensuring Quality: Benefits and Common Pitfalls

Ensuring quality during a pre-delivery inspection (PDI) is paramount for high-performance vehicle repairs. It’s the final quality control step before a vehicle leaves the workshop, ensuring it meets the highest standards. Benefits of thorough PDI include catching any minor issues early, enhancing customer satisfaction, and preserving the vehicle’s performance potential. A well-conducted PDI can also save time and money in the long run by preventing future repairs due to missed defects.

However, common pitfalls exist that can undermine these benefits. Inadequate training or haste during the inspection process may lead to oversights, resulting in defective vehicles leaving the shop. Poor communication between mechanics and inspectors can also contribute to errors. Moreover, focusing solely on visible components can neglect underlying issues like faulty electrical systems or misaligned frames (requiring frame straightening) that might require specialized services like auto body repairs or auto glass replacement.

Pre-delivery inspections are a vital step in ensuring high-performance vehicle repairs meet quality standards. By understanding the procedures, assessing key components thoroughly, and being aware of potential pitfalls, repair facilities can provide owners with peace of mind. This meticulous process not only guarantees optimal performance but also enhances customer satisfaction, making it an indispensable practice in the automotive industry. Implement these strategies to elevate your pre-delivery inspection routine and deliver top-tier results.