A pre-delivery inspection is a critical step in paintless dent repair (PDR), where experts thoroughly assess vehicle condition, document damage, and plan repairs for exceptional outcomes. This process guarantees high-quality standards, client satisfaction, accurate pricing, and builds trust through transparent damage evaluation. Skilled inspectors overcome challenges like subtle dents, complex panel interactions, and hidden damage to provide top-notch PDR services.

Before diving into paintless dent repair, a thorough pre-delivery inspection is paramount. This crucial step ensures high-quality outcomes and client satisfaction by identifying all damage and setting realistic expectations. By meticulously assessing the vehicle’s surface, technicians can plan repairs effectively, minimizing time and materials costs. Understanding best practices for pre-delivery inspection procedures, key visual assessment components, and common challenges empowers professionals to deliver exceptional service.

- Understanding Pre-Delivery Inspection Procedures

- Key Components of a Visual Assessment

- Benefits and Common Challenges in Pre-Inspection

Understanding Pre-Delivery Inspection Procedures

A pre-delivery inspection is a meticulous process that plays a vital role in ensuring high-quality standards for paintless dent repair services. It involves a comprehensive assessment of the vehicle’s condition before any work begins, allowing technicians to identify existing damage and plan repairs accordingly. This systematic approach is crucial for maintaining consistency and precision in car scratch repair or fender repair procedures.

During this inspection, experts carefully examine every inch of the vehicle’s exterior, paying close attention to dents, scratches, and any signs of previous repairs. By documenting these findings, they create a detailed report that serves as a roadmap for the restoration process. This ensures that every aspect of car restoration is executed with precision, resulting in exceptional outcomes and client satisfaction.

Key Components of a Visual Assessment

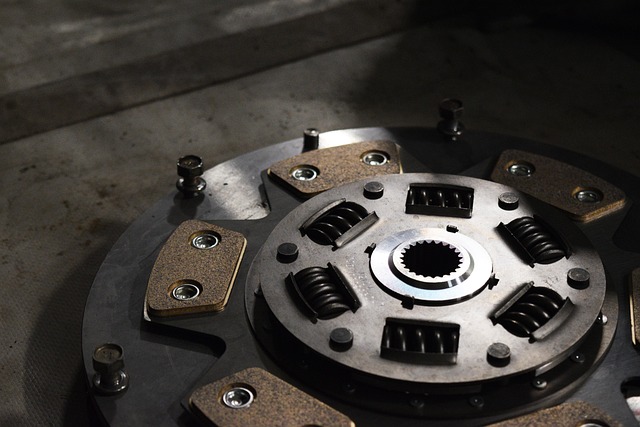

A comprehensive pre-delivery inspection is a cornerstone of successful paintless dent repair (PDR) jobs. During this meticulous process, highly trained technicians conduct a thorough visual assessment to identify all aspects of a vehicle’s condition, both inside and out. This includes not just the visible dents and scratches but also checking for any underlying damage that could impact the final repair outcome.

Key components of this assessment involve examining the car’s exterior surface for paint defects, misalignments, or signs of previous repairs. Technicians use specialized tools to detect changes in panel gaps and ensure each body panel is properly aligned. The interior is also inspected for any tears or stains in the upholstery, cracks in the dash, or maladjustment of trim pieces. By meticulously documenting these findings during the pre-delivery inspection, automotive body shop professionals can create a precise repair plan, ensuring that every detail—from subtle dings to major dents—is addressed, resulting in superior quality car dent repair services.

Benefits and Common Challenges in Pre-Inspection

Pre-delivery inspection is a vital step in the paintless dent repair process, offering numerous advantages for both the technician and the client. By thoroughly examining the car before any repairs begin, technicians can accurately assess the extent of damage, identify hidden issues, and provide precise quotes. This transparency builds trust between the shop and the customer, ensuring they are well-informed about the work required and associated costs.

While pre-inspection is beneficial, it also presents certain challenges. Car body shops must possess skilled inspectors who can detect subtle dents and scratches that might go unnoticed at first glance. Additionally, vehicle collision repair can involve complex geometry and panel interactions, making it tricky to predict the outcome of repairs without a comprehensive initial evaluation. Common challenges include misaligned panels, hidden damage behind trim pieces, and paint discrepancies, all of which require meticulous attention during the pre-delivery process.

A thorough pre-delivery inspection is an invaluable step in paintless dent repair, ensuring both customer satisfaction and business success. By implementing a structured visual assessment process, technicians can accurately estimate repairs, set expectations, and deliver high-quality results. While challenges may arise, such as varying lighting conditions or subtle dents, staying attuned to key components during the inspection allows for precise documentation and effective communication with clients. Embracing pre-delivery inspections as a standard procedure helps establish a reputation for quality work and fosters long-term client relationships.